Prefabricated Homes in US: 2026 Guide with Options and Pricing

Prefabricated homes have evolved from simple structures to sophisticated, customizable dwellings that offer quality, efficiency, and value. As the housing market continues to adapt to changing demands, prefabricated construction presents an increasingly viable alternative to traditional building methods. This comprehensive guide explores the construction techniques, market developments, design possibilities, timelines, and cost considerations that define prefabricated housing in 2026, helping you make informed decisions about this modern approach to homeownership.

The prefabricated housing industry has matured significantly, offering homebuyers a practical path to property ownership with reduced construction times and predictable costs. Modern prefabricated homes combine factory precision with on-site assembly, resulting in structures that meet or exceed traditional building standards while offering unique advantages in efficiency and customization.

Understanding Prefabricated Home Construction Methods

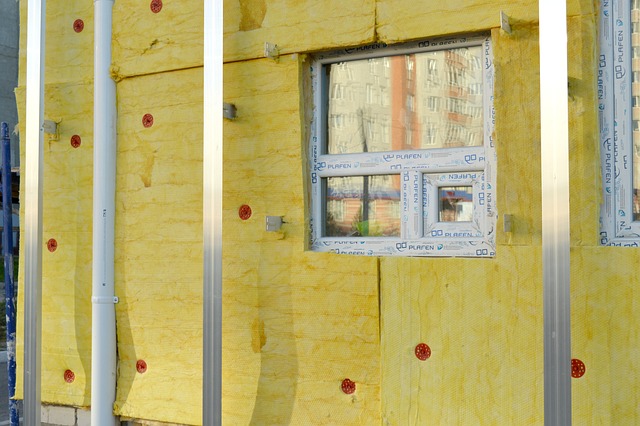

Prefabricated home construction encompasses several distinct approaches, each with specific characteristics. Modular homes are built in sections at factory facilities, then transported and assembled on permanent foundations. These structures typically consist of multiple modules joined together to create complete living spaces. Panelized homes involve wall panels, floor systems, and roof trusses manufactured off-site and assembled on location. Manufactured homes, built entirely in factories according to HUD code standards, arrive at sites nearly complete and are placed on chassis systems. Prefabricated construction offers controlled building environments, reduced weather delays, and consistent quality control throughout the manufacturing process. Factory settings enable precise measurements, specialized equipment use, and systematic inspections at each production stage.

Current Market Trends for Prefabricated Homes in 2026

The prefabricated housing sector continues expanding as buyers recognize the benefits of factory-built construction. Sustainability has become a central focus, with manufacturers incorporating energy-efficient systems, recycled materials, and renewable energy options into standard designs. Smart home technology integration is increasingly common, with prefabricated homes featuring automated climate control, security systems, and energy monitoring capabilities. Urban infill projects utilize prefabricated construction to address housing shortages in metropolitan areas where traditional building faces space and time constraints. Accessory dwelling units constructed using prefabricated methods provide flexible housing solutions for multigenerational living or rental income opportunities. The industry has also seen growing acceptance from lenders and appraisers, improving financing accessibility for prospective buyers. Material innovations continue advancing, with manufacturers adopting advanced insulation systems, durable exterior finishes, and structural components that enhance longevity and performance.

Available Design Options and Customization Features

Contemporary prefabricated homes offer extensive design flexibility, dispelling outdated perceptions of limited aesthetic choices. Buyers can select from numerous architectural styles including modern, traditional, farmhouse, and contemporary designs that complement various landscapes and personal preferences. Floor plan configurations range from compact single-module layouts to expansive multi-section arrangements with multiple bedrooms, bathrooms, and living areas. Exterior finish options include fiber cement siding, metal panels, wood cladding, brick veneer, and stucco applications that provide diverse visual appearances. Interior customization encompasses flooring materials, cabinetry styles, countertop selections, fixture choices, and paint colors that reflect individual tastes. Many manufacturers offer sustainable upgrades such as solar panel systems, high-efficiency HVAC equipment, low-flow plumbing fixtures, and enhanced insulation packages. Open floor plans, vaulted ceilings, large windows, and outdoor living spaces can be incorporated into prefabricated designs. Some manufacturers provide design software allowing buyers to visualize configurations and modifications before production begins.

Construction Timeline and Installation Process

Prefabricated home construction follows a structured timeline that typically progresses faster than traditional building methods. Site preparation occurs simultaneously with factory construction, including foundation installation, utility connections, and access road development. Manufacturing timelines generally span six to twelve weeks depending on home size, complexity, and customization level. Transportation logistics require careful planning, with modules or panels shipped via specialized trucks along predetermined routes to building sites. On-site assembly duration varies based on home type, with modular homes often assembled and enclosed within days, while panelized construction may require several weeks. Final completion involves connecting utilities, installing finish materials, conducting inspections, and obtaining occupancy certificates. Weather conditions affect on-site work but have minimal impact on factory production, contributing to more predictable completion schedules. Coordination between manufacturers, contractors, and local authorities ensures smooth progression through each construction phase.

Pricing Breakdown and Provider Comparison

Understanding cost structures helps buyers evaluate prefabricated home investments effectively. Base pricing typically ranges from $100 to $200 per square foot for modular homes, though luxury models may exceed $300 per square foot. Manufactured homes generally cost between $50 and $120 per square foot, representing the most economical prefabricated option. These figures include factory construction but exclude land, site preparation, foundation work, utility connections, transportation, and assembly costs. Site development expenses vary significantly based on location, terrain, and existing infrastructure, potentially adding $20,000 to $100,000 or more to total project costs. Customization choices, upgraded materials, and additional features increase base pricing accordingly.

| Provider | Home Type | Price Range (per sq ft) | Key Features |

|---|---|---|---|

| Clayton Homes | Manufactured/Modular | $50-$150 | Nationwide presence, diverse models, financing options |

| Blu Homes | Modular | $250-$400 | Contemporary designs, sustainable features, coastal focus |

| Champion Home Builders | Manufactured/Modular | $60-$140 | Customization options, energy efficiency, multiple brands |

| Method Homes | Modular | $200-$350 | Architectural designs, eco-friendly construction, West Coast availability |

| Palm Harbor Homes | Manufactured | $55-$120 | Variety of floor plans, quality construction, regional distribution |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Financing options for prefabricated homes have expanded, with conventional mortgages increasingly available for modular homes on permanent foundations. Manufactured homes may require specialized lending products with different terms and requirements. Total project budgets should account for permits, inspections, landscaping, driveways, and contingency funds for unexpected expenses. Regional variations in labor costs, material availability, and regulatory requirements significantly influence final pricing. Comparing multiple manufacturers and obtaining detailed quotes helps buyers understand complete cost implications and identify the best value for their specific needs and preferences.

Conclusion

Prefabricated homes represent a practical, efficient approach to residential construction that combines quality, customization, and value. Understanding construction methods, market trends, design options, timelines, and pricing enables informed decision-making throughout the home-buying process. As manufacturing techniques advance and industry acceptance grows, prefabricated construction continues offering viable solutions for diverse housing needs and budgets across the United States.