Prefabricated Homes Contemporary Options for Eco-Friendly Living

The housing market has experienced significant shifts in recent years, prompting many individuals and families to explore alternative building methods. Prefabricated homes, constructed off-site in controlled factory environments and assembled on location, have emerged as a viable solution for those seeking sustainable, cost-effective, and efficient housing. These structures combine modern design principles with environmentally conscious materials and processes, offering a fresh perspective on residential construction that addresses both affordability concerns and ecological responsibility.

The concept of building homes in sections away from their final location has evolved dramatically from its early industrial roots. Modern prefabricated construction incorporates advanced engineering, sustainable materials, and contemporary architectural design to create residences that rival traditional site-built homes in quality and aesthetic appeal. As environmental awareness grows and housing affordability becomes increasingly challenging, these factory-built structures present a practical alternative that merits serious consideration.

What Buyers Should Know About Prefabricated Homes

Understanding the fundamentals of prefabricated construction helps potential buyers make informed decisions. These homes are manufactured in climate-controlled facilities where precision equipment and standardized processes ensure consistent quality. The construction timeline typically ranges from several weeks to a few months, significantly shorter than conventional building methods. Buyers should recognize that prefabricated does not mean inferior; many manufacturers use materials equal to or exceeding those found in traditional construction. Building codes and regulations apply equally to prefabricated structures, and most models can be customized to reflect personal style preferences. Financing options have expanded as lenders become more familiar with this construction method, though buyers should research specific requirements in their area. Land preparation, foundation work, and utility connections remain necessary steps that occur on-site, adding to the overall project timeline and budget.

What to Expect When Choosing a Prefabricated Home

The selection process involves several key considerations that differ from purchasing a traditional home. Prospective buyers typically begin by researching manufacturers and reviewing available floor plans, with many companies offering virtual tours and design consultations. Customization levels vary by manufacturer, ranging from minor cosmetic changes to comprehensive design modifications. Site assessment proves critical, as the land must accommodate delivery trucks and cranes for assembly. Buyers should budget for foundation preparation, utility hookups, and any required permits before the home arrives. The assembly phase usually takes days to weeks, depending on the home’s complexity and size. Interior finishing work, including flooring, cabinetry, and fixtures, may be completed at the factory or on-site. Buyers should clarify warranty coverage, which typically separates structural components from appliances and finishes. Transportation costs can vary significantly based on distance from the manufacturing facility, making local or regional manufacturers potentially more economical.

Why Some Buyers Are Turning to Prefabricated Homes as Housing Costs Rise

Economic pressures have prompted many to reconsider traditional homeownership paths. Prefabricated construction often reduces labor costs through factory efficiency and minimizes material waste through precise manufacturing processes. The controlled environment eliminates weather-related delays that can extend timelines and increase expenses in conventional building. Energy efficiency represents another financial advantage, as many prefabricated homes incorporate superior insulation and modern HVAC systems that lower long-term utility costs. The speed of construction allows buyers to occupy their homes sooner, reducing rental payments or temporary housing expenses. Some buyers appreciate the transparency of pricing, as many manufacturers provide detailed cost breakdowns upfront. Market volatility affects prefabricated homes differently than traditional real estate, potentially offering more predictable pricing. The ability to place these homes on owned land in rural or suburban areas provides access to homeownership in regions where traditional housing inventory remains limited.

Real-World Cost Insights and Provider Comparisons

Understanding the financial landscape helps buyers set realistic expectations. Prefabricated home costs vary widely based on size, design complexity, materials, and manufacturer. Basic modular units may start around $50,000 to $80,000 for smaller structures, while luxury custom designs can exceed $300,000 or more. Per-square-foot pricing typically ranges from $80 to $200, compared to $150 to $400 for traditional site-built homes in many markets. Additional expenses include land purchase, site preparation, foundation installation, utility connections, and transportation, which collectively can add $30,000 to $100,000 or more to the total project cost.

| Provider Type | Cost Range | Key Features |

|---|---|---|

| Economy Manufacturers | $50,000 - $120,000 | Basic designs, standard materials, limited customization |

| Mid-Range Providers | $120,000 - $250,000 | Moderate customization, quality finishes, energy-efficient options |

| Premium Builders | $250,000 - $500,000+ | Extensive customization, luxury materials, advanced sustainability features |

| Tiny Home Specialists | $30,000 - $100,000 | Compact designs, mobile options, minimalist living solutions |

| Container Home Companies | $40,000 - $150,000 | Recycled materials, modern aesthetic, modular expansion capability |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Environmental Benefits and Sustainable Features

The ecological advantages of prefabricated construction extend beyond marketing claims. Factory production minimizes material waste through precise cutting and efficient use of resources, with some manufacturers recycling up to 90 percent of construction scraps. Reduced transportation needs for materials and workers lower the carbon footprint compared to traditional building sites. Many prefabricated homes incorporate sustainable materials such as reclaimed wood, recycled steel, and low-VOC finishes that improve indoor air quality. Energy-efficient design features, including enhanced insulation, triple-pane windows, and solar panel integration, reduce long-term environmental impact. Water conservation systems, such as low-flow fixtures and rainwater collection, are increasingly standard in eco-focused designs. The controlled manufacturing environment allows for more precise installation of insulation and weatherproofing, eliminating gaps that compromise energy efficiency. Some manufacturers pursue green building certifications, demonstrating commitment to environmental standards throughout the construction process.

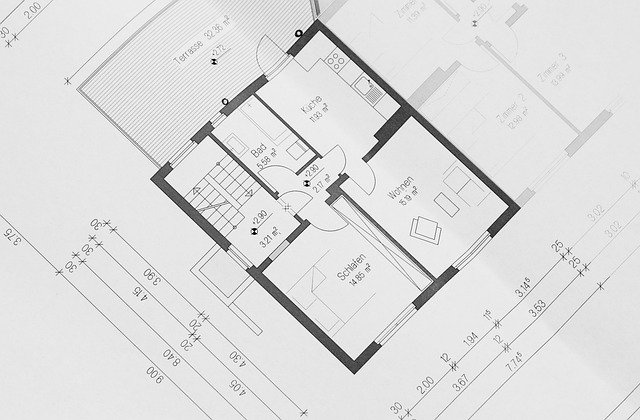

Design Flexibility and Modern Aesthetics

Contemporary prefabricated homes challenge outdated perceptions of uniformity and limited style options. Architectural firms increasingly collaborate with manufacturers to create distinctive designs that reflect current trends. Open floor plans, large windows, and seamless indoor-outdoor transitions characterize many modern prefabricated models. Exterior finishes range from traditional siding to contemporary metal panels, natural wood, and stucco, allowing homes to blend with or stand out from their surroundings. Interior customization options include kitchen layouts, bathroom configurations, and bedroom arrangements that accommodate diverse lifestyle needs. Smart home technology integration has become standard in many models, with pre-wired systems for automation, security, and energy management. Modular design allows for future expansion, with some homes engineered to accommodate additional sections as families grow. The combination of factory precision and architectural creativity produces homes that reflect individual taste while maintaining structural integrity and efficiency.

Prefabricated homes represent a meaningful shift in residential construction, offering practical solutions to contemporary housing challenges. The combination of reduced construction timelines, potential cost savings, environmental benefits, and design flexibility makes this building method increasingly relevant. As manufacturing techniques advance and consumer awareness grows, prefabricated construction continues to gain acceptance as a legitimate and attractive housing option. Prospective buyers who thoroughly research manufacturers, understand the complete cost structure, and carefully plan site preparation can successfully navigate the process and achieve their homeownership goals through this innovative approach.