Exploring the World of Laser Suppliers: A Comprehensive Guide

The laser industry has transformed manufacturing, crafting, and industrial processes across countless sectors. From precision cutting to intricate engraving, laser technology offers unmatched accuracy and versatility. Whether you're a small business owner looking to expand capabilities or an industrial manufacturer seeking reliable equipment, understanding the laser supplier landscape is crucial for making informed decisions that align with your operational needs and budget constraints.

Modern laser technology has revolutionized how businesses approach precision work, from manufacturing components to creating custom products. The market offers diverse laser solutions, each designed for specific applications and industries. Selecting the right laser supplier involves understanding various factors including technology types, service quality, and long-term value propositions.

Understanding Laser Technology

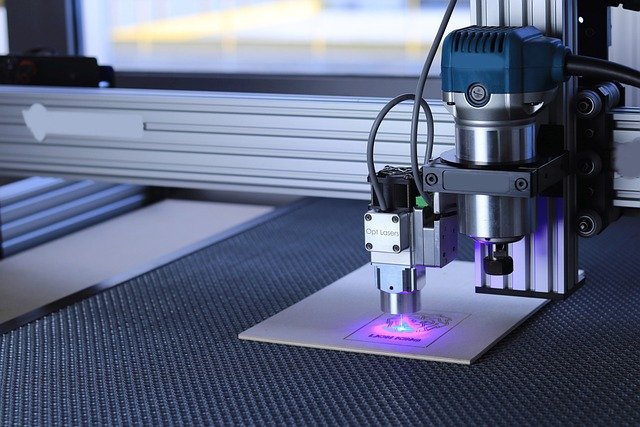

Laser systems operate on different principles depending on their intended use. CO2 lasers excel at cutting and engraving organic materials like wood, acrylic, and leather, while fiber lasers demonstrate superior performance with metals and harder materials. Diode lasers offer cost-effective solutions for lighter applications, making them popular among hobbyists and small businesses. Each technology type requires specific expertise from suppliers, influencing both initial investment and ongoing support requirements.

The power output of laser systems directly impacts their capabilities and applications. Lower wattage systems typically handle thinner materials and detailed engraving work, while higher power units can cut through thick metals and process materials at faster speeds. Understanding these specifications helps narrow down supplier options based on your specific operational requirements.

Choosing the Right Laser Supplier

Reliable laser suppliers distinguish themselves through comprehensive support services, technical expertise, and product quality assurance. Established suppliers typically offer training programs, ensuring operators can maximize equipment potential while maintaining safety standards. Technical support availability becomes crucial when equipment issues arise, as downtime directly impacts productivity and profitability.

Supplier reputation within the industry often reflects their commitment to quality and customer satisfaction. Researching customer testimonials, case studies, and industry certifications provides valuable insights into supplier reliability. Additionally, suppliers who offer demonstration opportunities allow potential buyers to evaluate equipment performance before making purchasing decisions.

Warranty coverage and service agreements vary significantly among suppliers, affecting long-term ownership costs. Comprehensive warranty programs protect against manufacturing defects and provide peace of mind during initial operation periods. Service agreements ensure regular maintenance and priority support, extending equipment lifespan and maintaining optimal performance levels.

Evaluating Cost and Value

Laser equipment pricing reflects numerous factors including technology type, power output, build quality, and included features. Entry-level systems suitable for small businesses typically start around $3,000-$8,000, while industrial-grade equipment can range from $15,000 to over $100,000. These price ranges vary based on specifications, supplier positioning, and market conditions.

Operational costs extend beyond initial purchase prices, encompassing maintenance, consumables, and energy consumption. Regular maintenance requirements, replacement part availability, and service costs significantly impact total ownership expenses. Energy-efficient models may command higher upfront prices but deliver savings through reduced operational costs over time.

| Supplier Category | Equipment Type | Price Range | Key Features |

|---|---|---|---|

| Entry-Level Suppliers | Desktop CO2/Diode | $3,000-$8,000 | Basic software, limited power |

| Mid-Range Suppliers | Professional CO2/Fiber | $8,000-$25,000 | Advanced features, better support |

| Industrial Suppliers | High-Power Systems | $25,000-$100,000+ | Maximum precision, full service |

| Specialized Suppliers | Custom Solutions | Variable | Tailored applications, expert consultation |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Value assessment requires considering factors beyond initial pricing, including supplier reputation, support quality, and equipment longevity. Suppliers offering comprehensive training, responsive technical support, and reliable warranty coverage often provide better long-term value despite potentially higher upfront costs. Additionally, suppliers with established parts distribution networks ensure continued operation and minimize downtime risks.

Financing options available through suppliers can make advanced equipment more accessible to businesses with limited capital. Lease programs, equipment financing, and trade-in opportunities provide flexibility in acquiring necessary technology while managing cash flow requirements. These arrangements often include maintenance packages, further simplifying ownership responsibilities.

The laser supplier landscape continues evolving with technological advances and changing market demands. Successful supplier relationships depend on clear communication of requirements, thorough evaluation of options, and consideration of long-term operational needs. By understanding technology fundamentals, supplier capabilities, and cost structures, businesses can make informed decisions that support their growth objectives while maximizing return on investment.